Applications and Implications

Individual assignment:

The assignment is to Propose a final project masterpiece that integrates the range of units covered, answering:

- What will it do?

- Who's done what beforehand?

- What will I design?

- What materials and components will be used?

- Where will come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

The requirements that must meet my project are also given in the assignment

My project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design, and production, embedded microcontroller interfacing and programming, system integration, and packaging

Where possible, I should make rather than buy the parts of my project

Projects can be separate or joint, but need to show my mastery of the skills and be independently operable

What will it do?

The primary function of the DIS-CARD project is to distribute playing cards among players for various card games such as UNO, poker, etc. The device accepts input for the number of players and the number of cards per player, and then automatically distributes the cards accordingly.

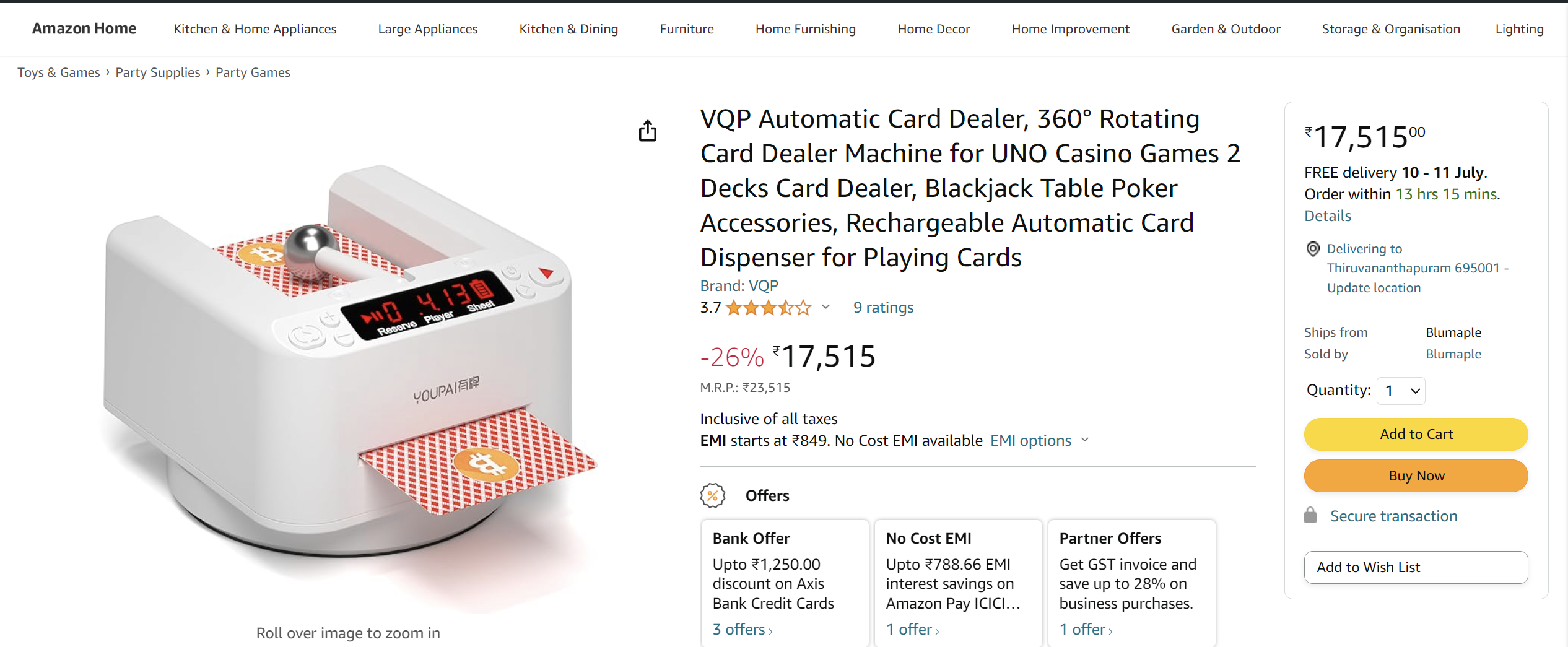

Who's done what beforehand?

Existing products on the market can distribute cards among players, but they tend to be expensive. For example, similar products on Amazon cost around 18,000 INR. The DIS-CARD project aims to create a more affordable solution that still provides efficient card distribution, costing only around 1,000 INR.

What will I design?

I will design the entire DIS-CARD product, including:

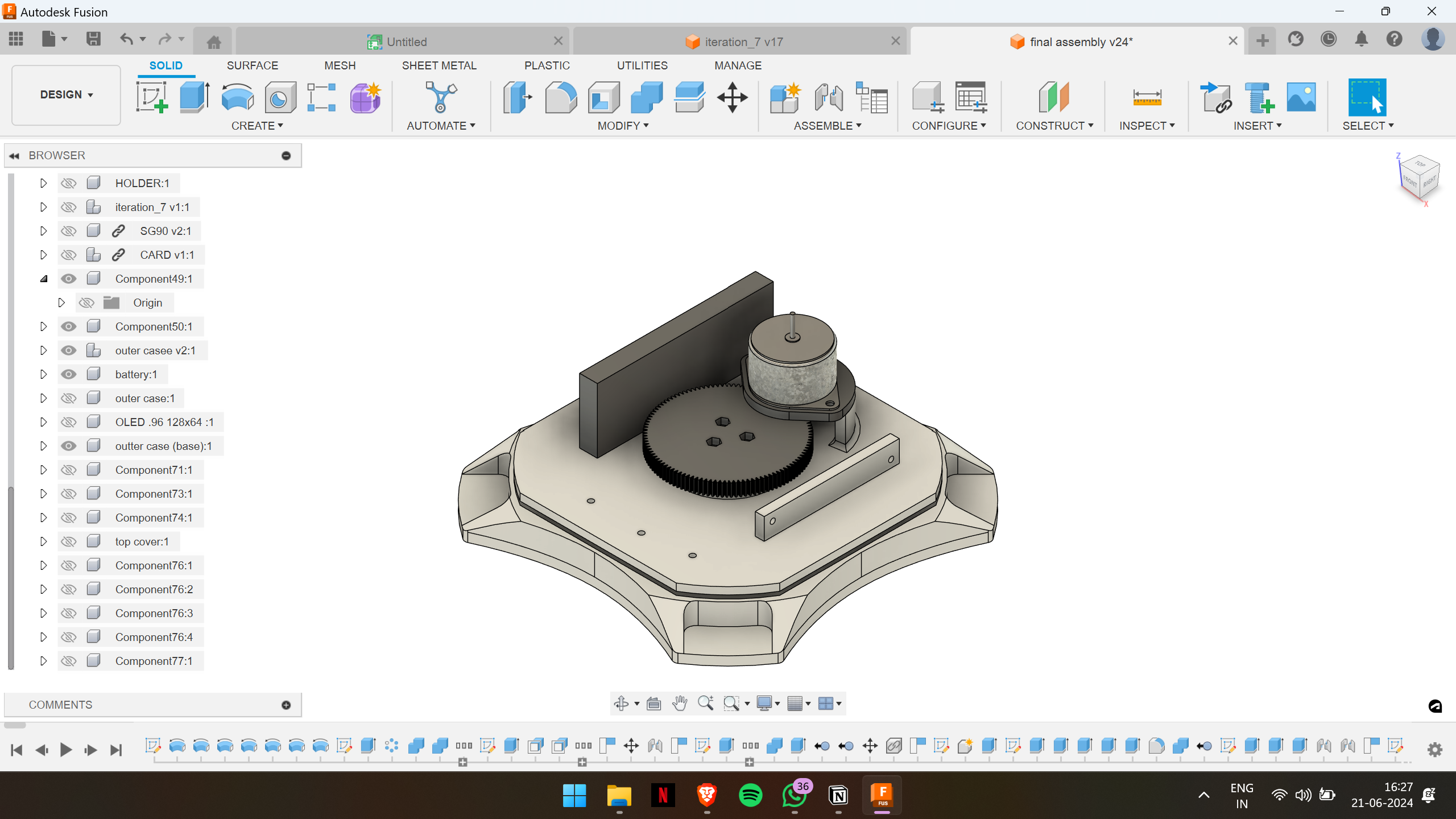

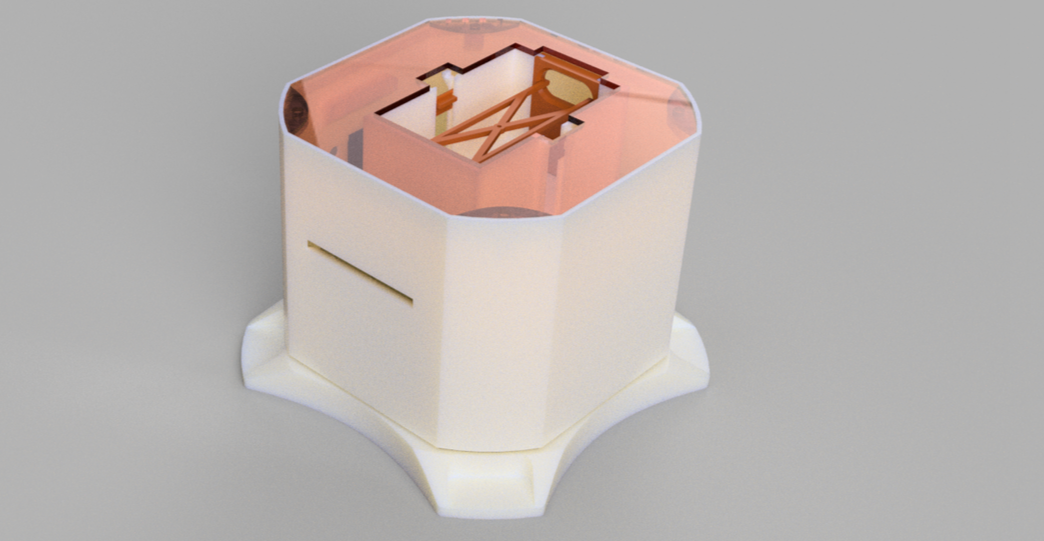

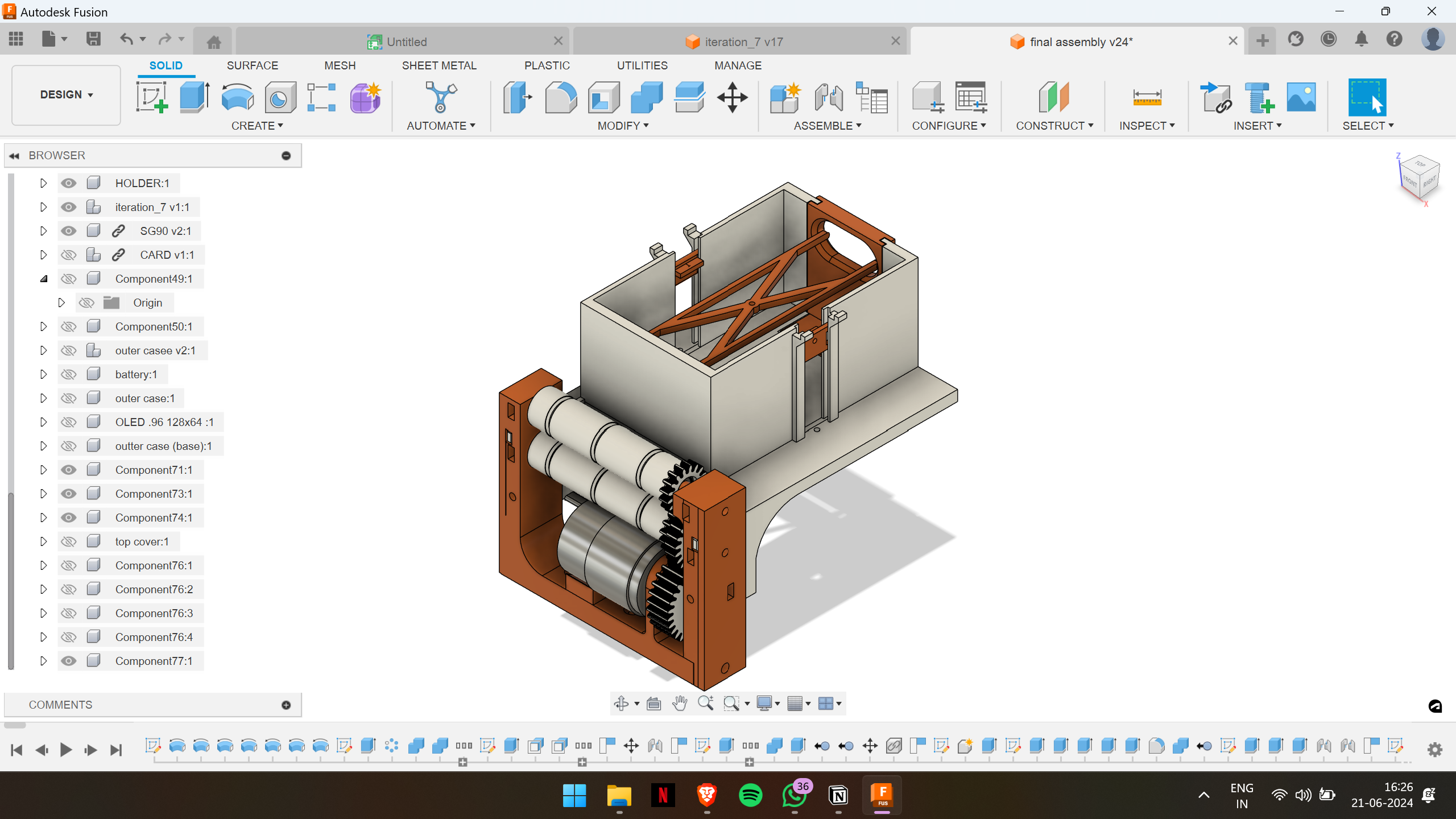

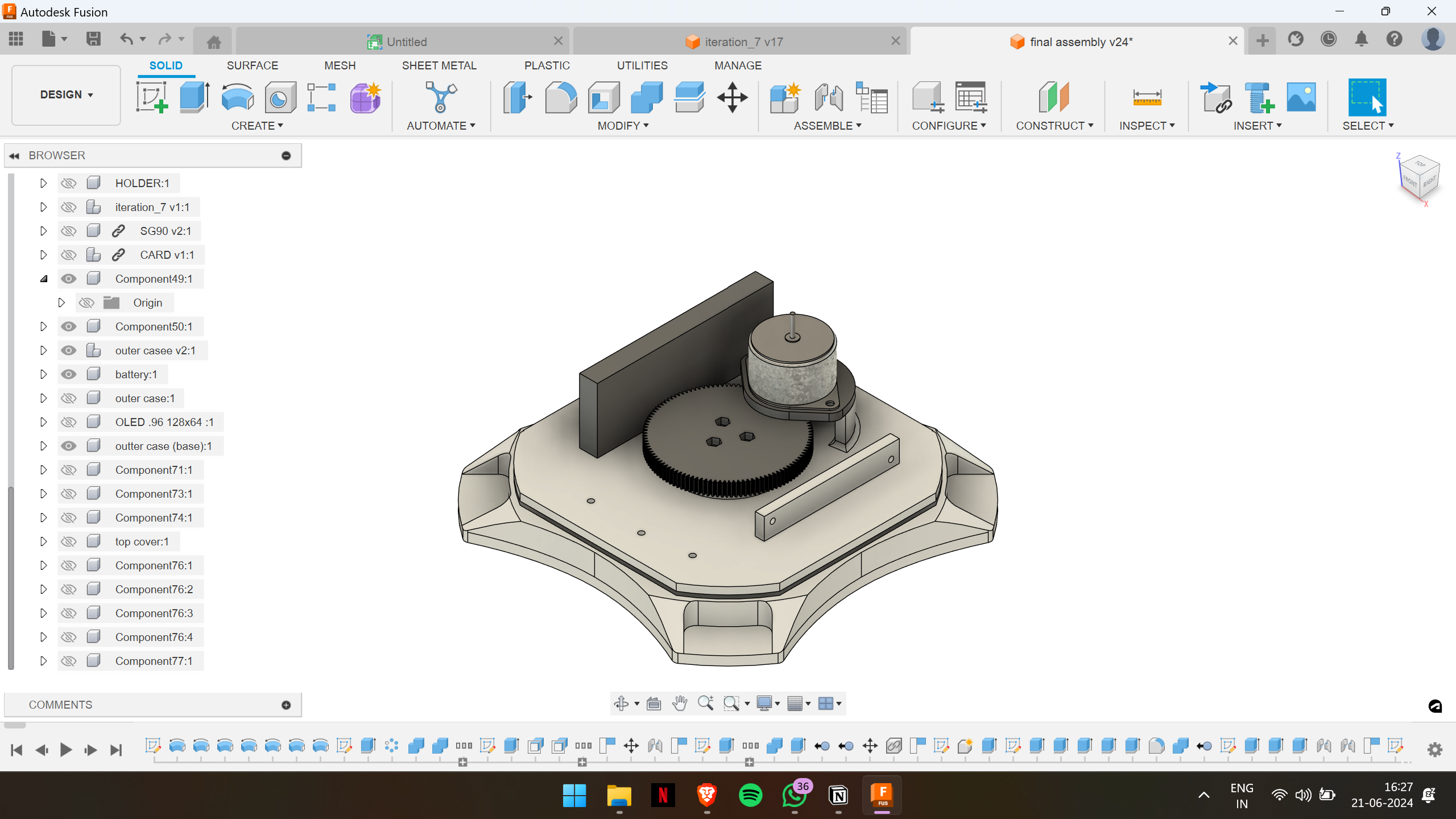

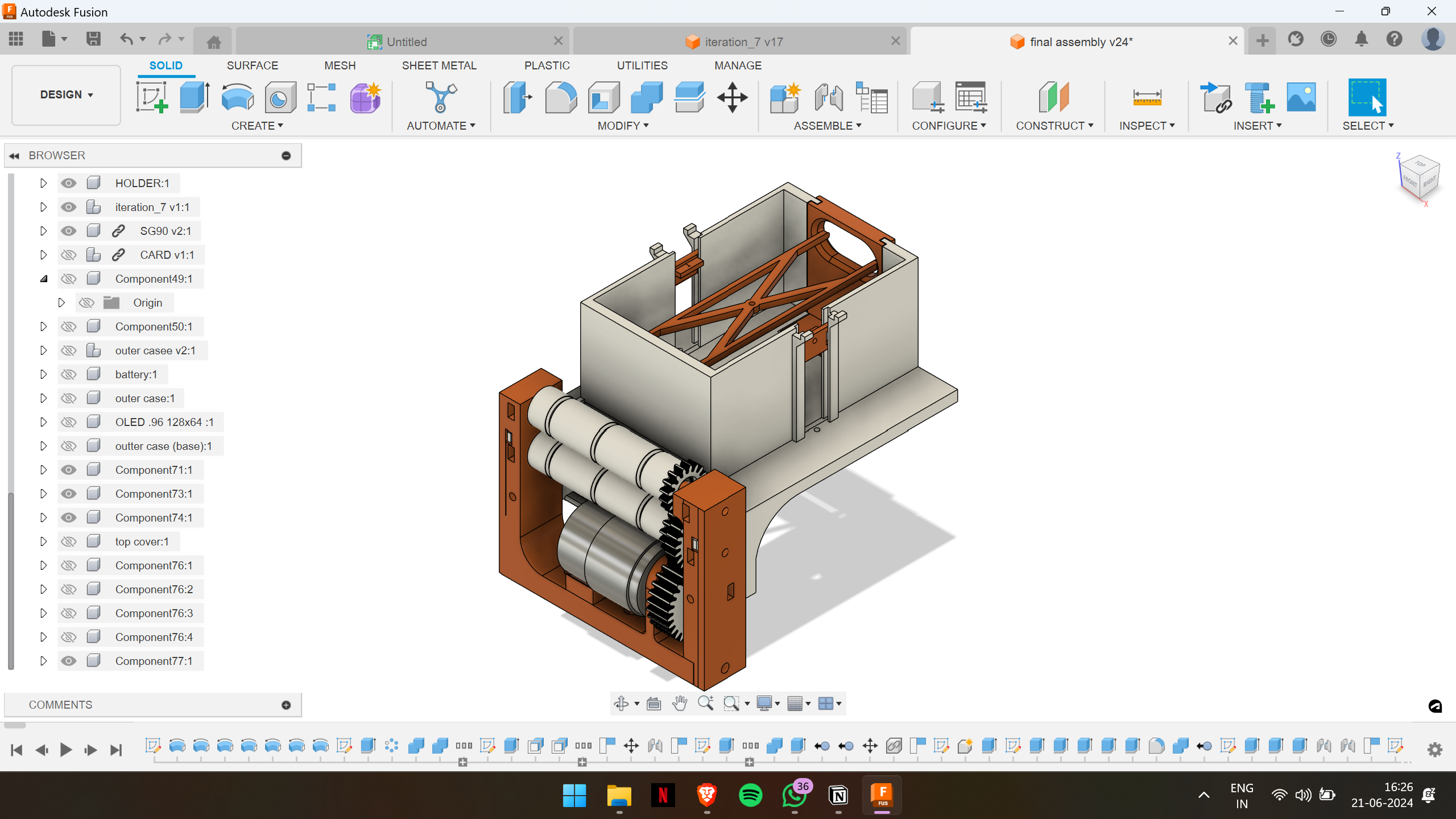

- CAD Design: Creating the complete 3D design of the product.

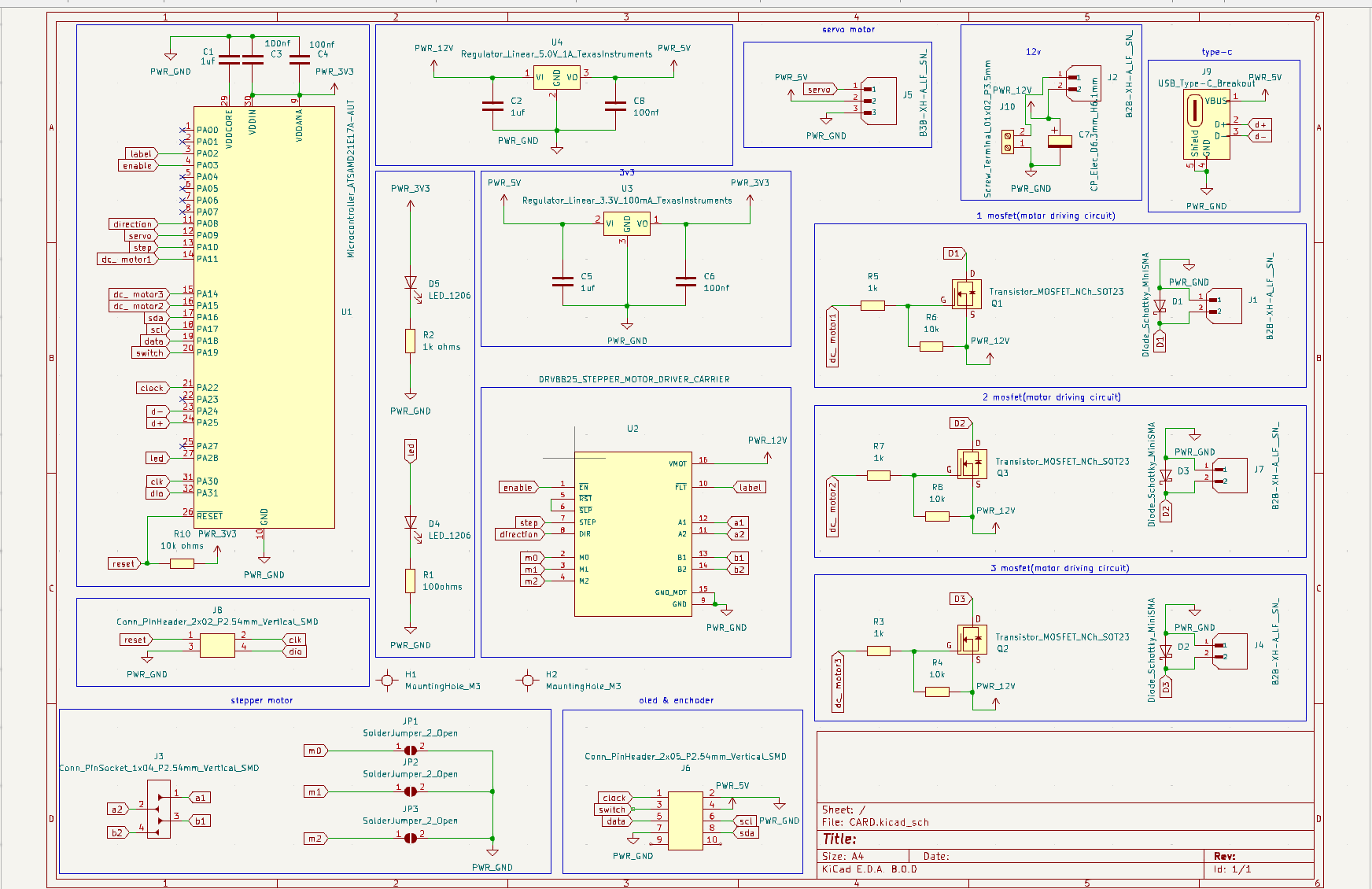

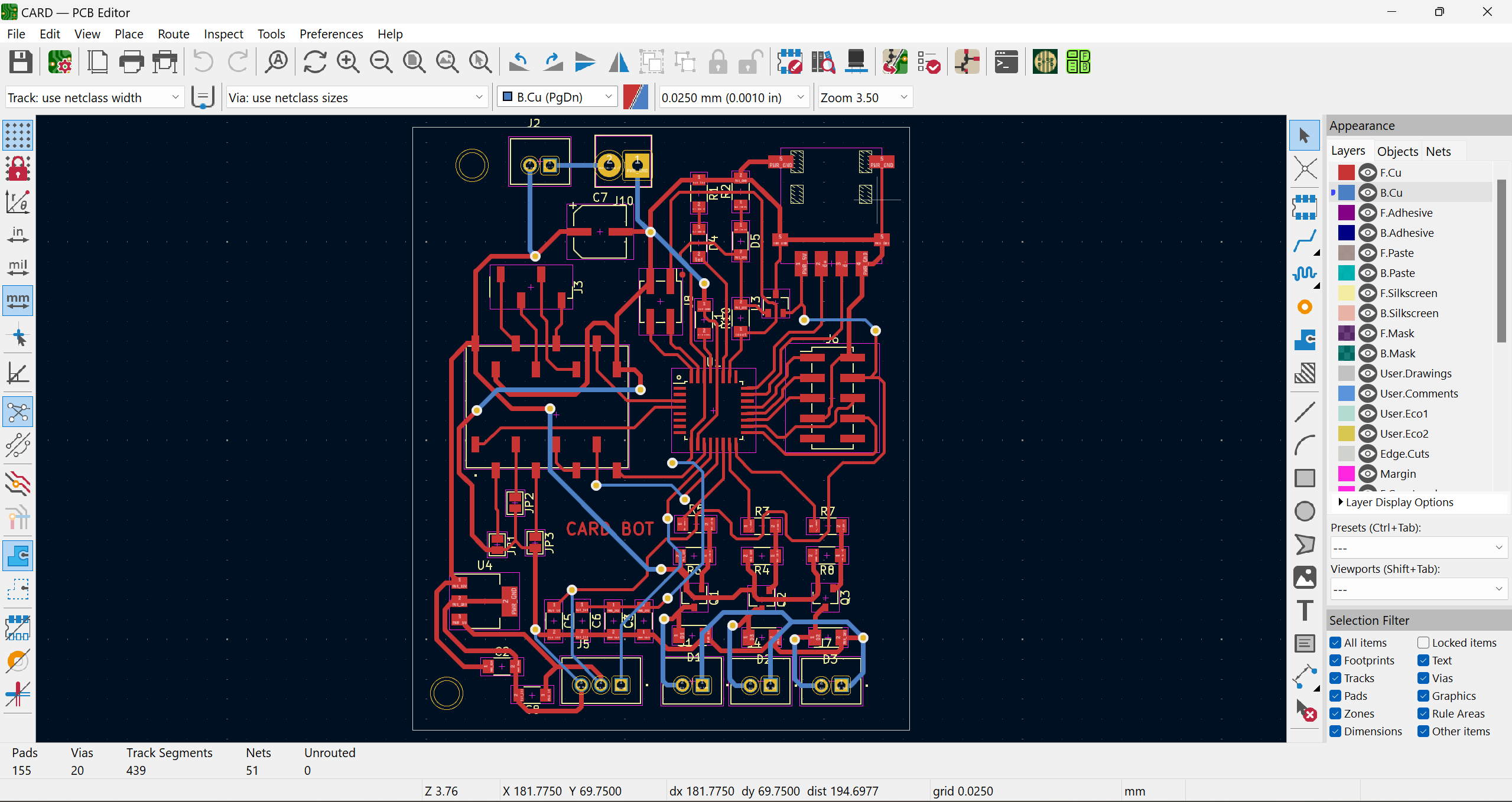

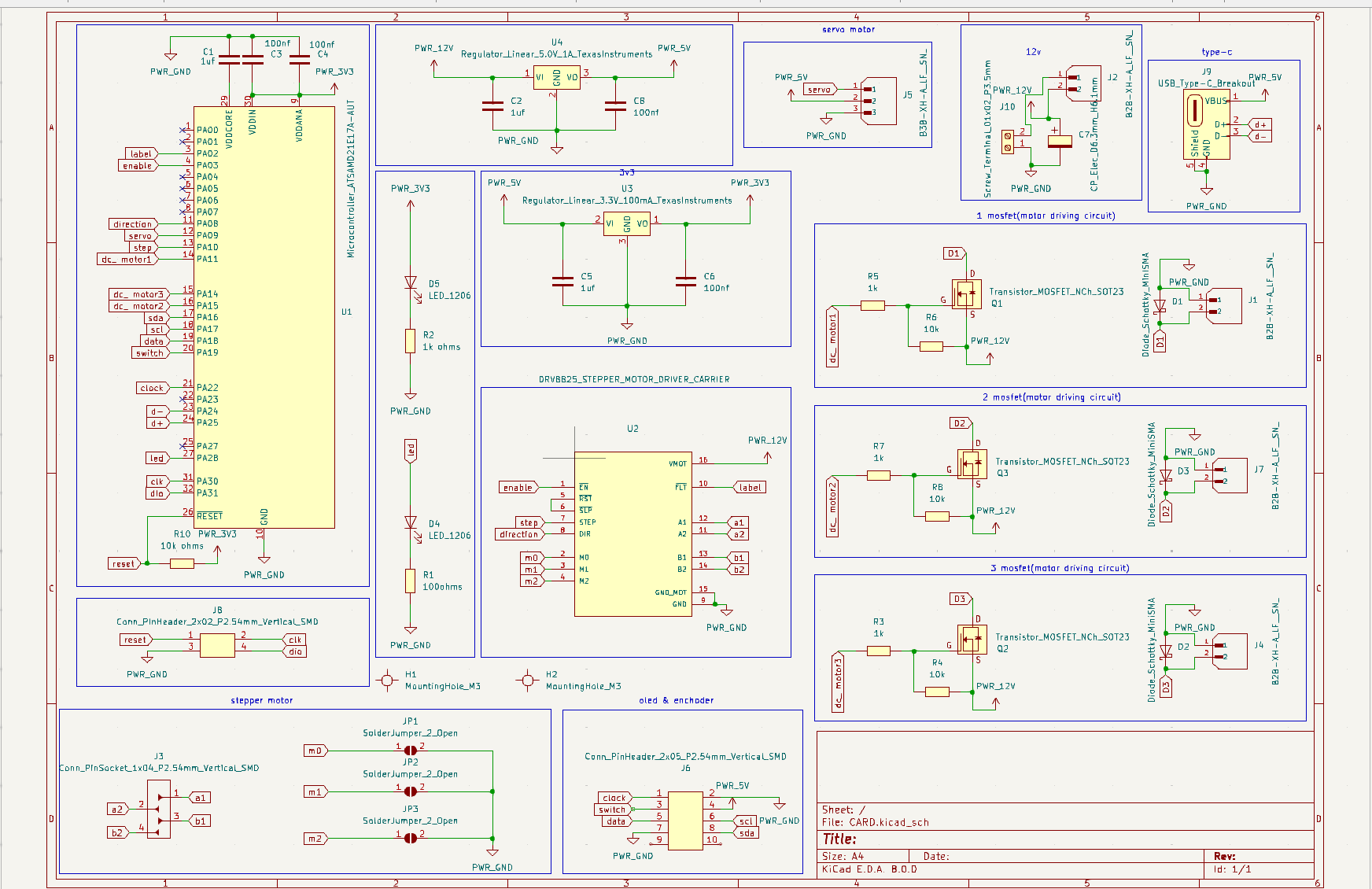

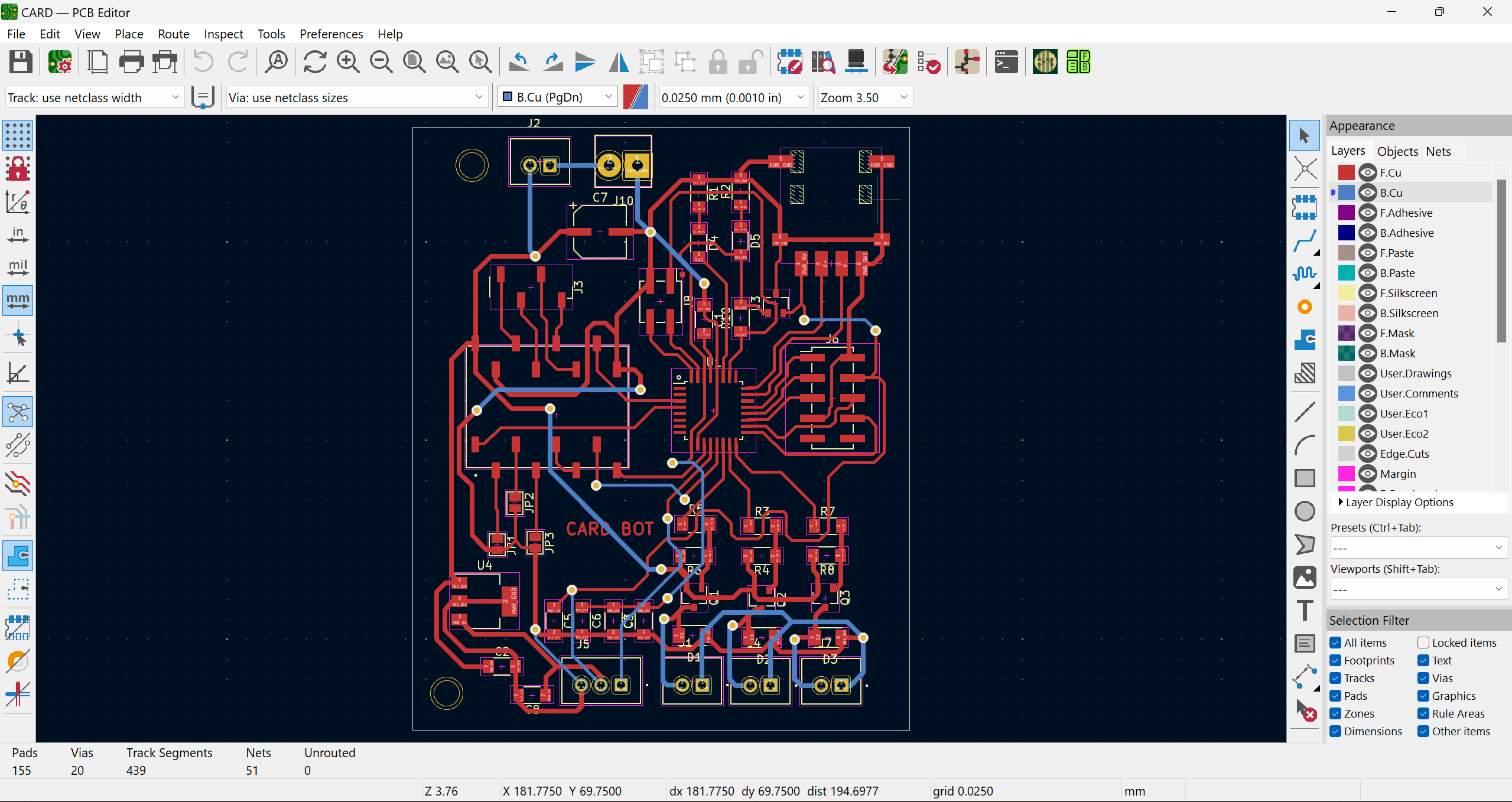

- Electronics: Designing and integrating the necessary electronic components.

What materials and components will be used, where will they come from, and how much will they cost?

| SL:NO | PART NAME | QUNATITY | PRICE | TOTAL | SOURCE |

|---|---|---|---|---|---|

| 1 | DC MOTOR | 1 | ₹38 | ₹38 | FABLAB INVENTORY |

| 2 | SERVO MOTOR | 1 | ₹140 | ₹140 | FABLAB INVENTORY |

| 3 | STEPPER MOTOR | 1 | ₹170 | ₹170 | FABLAB INVENTORY |

| 4 | ROTORY ENCHODER | 1 | ₹40 | ₹40 | FABLAB INVENTORY |

| 5 | OLED SCREEN | 1 | ₹250 | ₹250 | FABLAB INVENTORY |

| 6 | ACYRLIC SHEET | .5 sq ft | ₹100 | ₹100 | FABLAB INVENTORY |

| 7 | 3D PRINTING | 18 hrs | ₹100 | ₹1800 | FABLAB INVENTORY |

| 8 | M3 NUTS AND BOLTS | 15 | ₹5 | ₹125 | FABLAB INVENTORY` |

| 9 | M4 NUTS AND BOLTS | 5 | ₹5 | ₹25 | FABLAB INVENTORY |

| 10 | PCB | .5hrs | ₹150 | ₹75 | FABLAB INVENTORY |

| 11 | RUBBER BANDS | 20 | ₹.5 | ₹10 | LOCAL SHOP |

| TOTAL | ₹2773 |

the electronics BOM will be added to the final project page

What parts and systems will be made?

-

Custom Parts:

-

Modified 180-degree servo to 360-degree servo.

I have modified the 360 servo by cutting the stopper in the servo motor gear and the shaft that turns the potentiometer in the servo motor. The detailed version will be documented in the final project week.

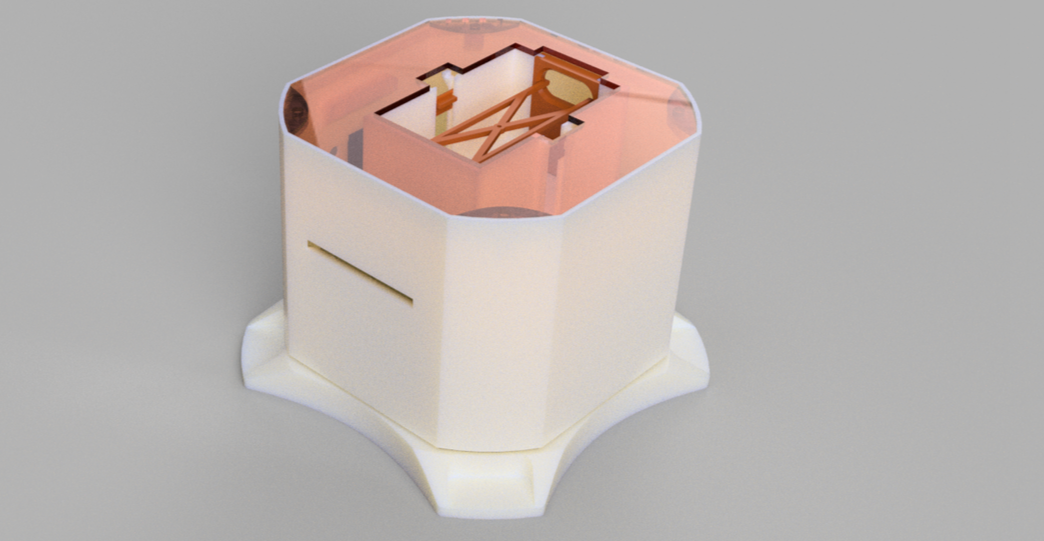

- 3D printed components for the card distribution mechanism.

- Laser cut components.

-

Modified 180-degree servo to 360-degree servo.

What processes will be used?

- Laser Cutting: For precise cutting of components.

- 3D Printing: For creating custom parts and housing.

- Circuit Designing: Creating the electronic circuit layouts.

- PCB Milling: Manufacturing the printed circuit boards.

- Soldering and Assembling: Integrating the electronic components.

- Embedded Programming: Programming the microcontroller to control the mechanisms.

What questions need to be answered?

- Will the project enhance the fun of playing card games?

- Will the design be aesthetically pleasing?

- Are the gear ratios suitable for the operation?

- Will the stepper motor and turntable gear mesh correctly?

- Will the menu system properly take and process input?

- Will the turntable mechanism operate according to the input?

- Will the cards be distributed one at a time without jamming?

How will it be evaluated?

Success Criteria:

- The DIS-CARD system should distribute cards effectively according to user input.

- The menu system should accept and process inputs accurately.

- The turntable mechanism should function smoothly and align with the inputs given.

- Cards should be distributed one at a time without jamming or errors.

- The design should be aesthetically pleasing and user-friendly.

- The project should utilize the knowledge and skills acquired during the FAB Academy effectively.

Final Evaluation:

The project will be considered successful if it meets the above criteria and demonstrates reliable performance using the available materials and processes.

Future scope

Currently, the available card distributor is sold for around 18,000 INR. With this open-source design, we can build it using the resources available in the lab, reducing the cost to 1/6 of the actual price.

PROJECT DEVELOPMENT

What tasks have been completed, and what tasks remain?

Completed Tasks:

Remaining Tasks:

- Fabrication and testing of the turntable mechanism.

- Fabrication of the outer case.

- Resolving the issue of cards getting stuck in the throwing mechanism.

- Final programming adjustments and testing.

What's working? What's not?

Working:

-

The card-throwing mechanism is functioning properly.

Not Working:

- There is an issue with the card throwing mechanism occasionally getting cards stuck. This issue needs to be addressed.

When will it be completed?

The project will be completed three days before the presentation date, the 10th. This means the target completion date is the 7th.

| Date | Day | Task |

|---|---|---|

| 24-05-2024 | Friday | mechanism (card throwing) |

| 25-05-2024 | Saturday | mechanism testing |

| 26-05-2024 | Sunday | rest |

| 27-05-2024 | Monday | CAD |

| 28-05-2024 | Tuesday | CAD |

| 29-05-2024 | Wednesday | Fabrication & Assembly |

| 30-05-2024 | Thursday | electronics design |

| 31-05-2024 | Friday | milling and soldering |

| 01-06-2024 | Saturday | programming |

| 02-06-2024 | Sunday | rest |

| 03-06-2024 | Monday | debugging |

| 04-06-2024 | Tuesday | prepare the presentation |

| 05-06-2024 | Wednesday | video |

| 06-06-2024 | Thursday | editing |

| 07-06-2024 | Friday | final presentation |

What have you learned?

To push one card at a time, I initially used a 180-degree servo motor. However, during testing, I realized that a 360-degree servo would be more suitable for my purpose. Since a 360-degree servo was not available in the lab, I discovered that a 180-degree servo could be modified into a 360-degree one. This led me to learn more about servos.

Initially, I began with a single roller to throw the card, but there were issues with that concept. Then, I came up with another idea: adding an extra roller coupled with the first roller. The card would be thrown between the two rollers, and this proved to be successful.